Welcome to ZaaK Technologies

We have ‘reached the limits’ of the planet’s natural resources

Unsustainable use of natural resources is having a severe impact on our environment. With the megatrend of urbanization and the increasing number of people living in cities, it is expected that natural resources such as sand and aggregates will continue to be depleted without replenishment.

ZaaK has been researching and developing innovative technologies to upcycle mineral wastes and by-products into value-added products for sustainable management of our natural resources. Our commitment is to give new life to these unused by-products or waste materials.

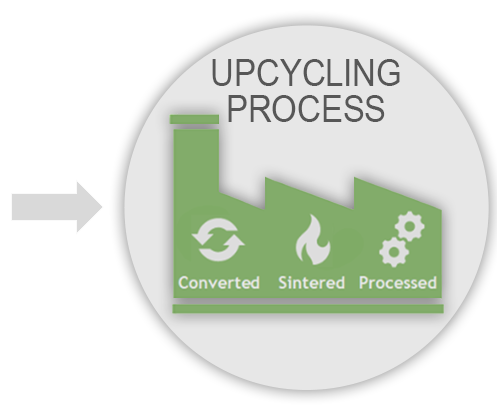

With its proprietary technologies, ZaaK offers a single step solution to the environmental impacts from mineral wastes and by-products. ZaaK’s upcycling technologies transform unused wastes and by-products into sustainable lightweight sand, called Lypors®. It is an ideal secondary raw material as a substitute to natural sand for use in the construction and other industries.

The challenges faced by producers of mineral wastes and by-products require viable and forward-looking solutions. To safeguard our socio-economic future, technologies that promote the achievement of sustainable development goals and veer towards circular economy are greatly needed.

By upcycling these wastes and by-products into high performance building materials ZaaK is providing a progressive solution to drastically reduce disposal problems, and pushing the waste-producing industries like thermal power, alumina and waste-to-energy plants towards a zero-waste scenario.

ZaaK’s processes ensure these wastes and by-products can be effectively utilized instead of being disposed or deposited. At the same time, it offers an ecological secondary raw material to the construction industry.

Products.

xxxxxxxxxxxxxxxxxxxxxxxxxxxx

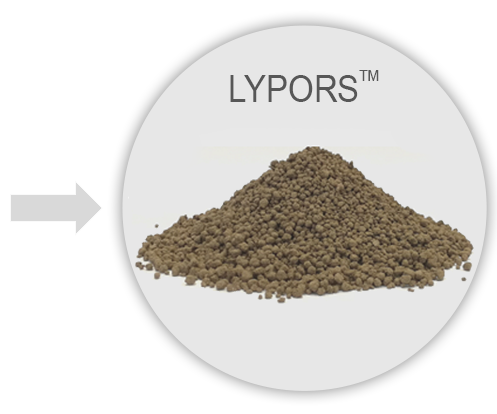

Lypors®

What is Lypors®:

Lypors® is a well size-graded lightweight sand manufactured from mineral wastes and by-products. It is a premium quality and a cost-effective construction sand material with diverse applications.

Where Lypors® can be used:

Lypors® can be used in different applications such as:

• Lightweight concrete

• Lightweight masonry mortar

• Thermal insulating plaster

• Lightweight roof tiles

• Lightweight façade

• Tile adhesive

• Flooring and others

Benefits of Using Lypors®:

• Ready to use

• Superior and consistent quality

• Well-balanced between lightweight and good strength

• Thermal and sound insulation

• Longer service life of buildings/infrastructures

Download the Datasheet to learn more about Lypors®

Lyplast®

What is LyplastTM?

Lyplast® is classified as a lightweight plastering mortar in accordance with DIN EN 998-1:2016 and covers the strength classes CS I and CS II.

Where Lyplast® can be used:

Lyplast® is suitable for all wall structures and can be used for both internal and external plastering. It has excellent heat-insulating properties and can be applied directly on the highly absorbent substrate without priming.

Benefits of Using Lyplast®:

• Lightweight – easy to lift, transport and plaster

• Thermal insulating

• Excellent workability

• Less rebound

• Excellent surface finishing

• Good adhesion on various substrate

• Improves labor productivity

Download the Datasheet to learn more about LyplastTM

Lytar®

What is Lytar®?

Lytar® is a lightweight masonry mortar in accordance with DIN EN 998-2:2016 and covers the strength classes from M5 to M15.

Where LytarTM can be used:

LytarTM is suitable for the construction of loaded and unloaded masonry and applicable for interior and exterior use for bricking up highly insulating wall construction materials.

Benefits of Using LytarTM:

• Lightweight – easy to lift, transport and apply

• Excellent strength

• Good workability

• Good adhesion

• Improves labor productivity

Download the Datasheet to learn more about LytarTM

Lycrete®

What is Lycrete®?

Lycrete® is a lightweight dry ready-mix concrete in accordance with DIN EN 206-1:2000

Where Lycrete® can be used:

It is suitable for various concrete work such as the production of screed constructions, foundations, door, and window lintels

Benefits of Using Lycrete®:

• Excellent strength-to-weight ratio

• Thermal insulating

• Good workability

• Fire resistance

• Energy savings from heating/cooling buildings

Download the Datasheet to learn more about LycreteTM

Input streams

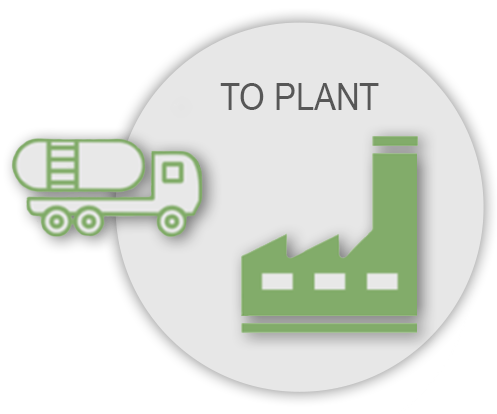

From wastes to Lypors®

As a Greentech company and a pioneer in upcycling, ZaaK envisions the establishment of a new standard for secondary raw materials on the global market.

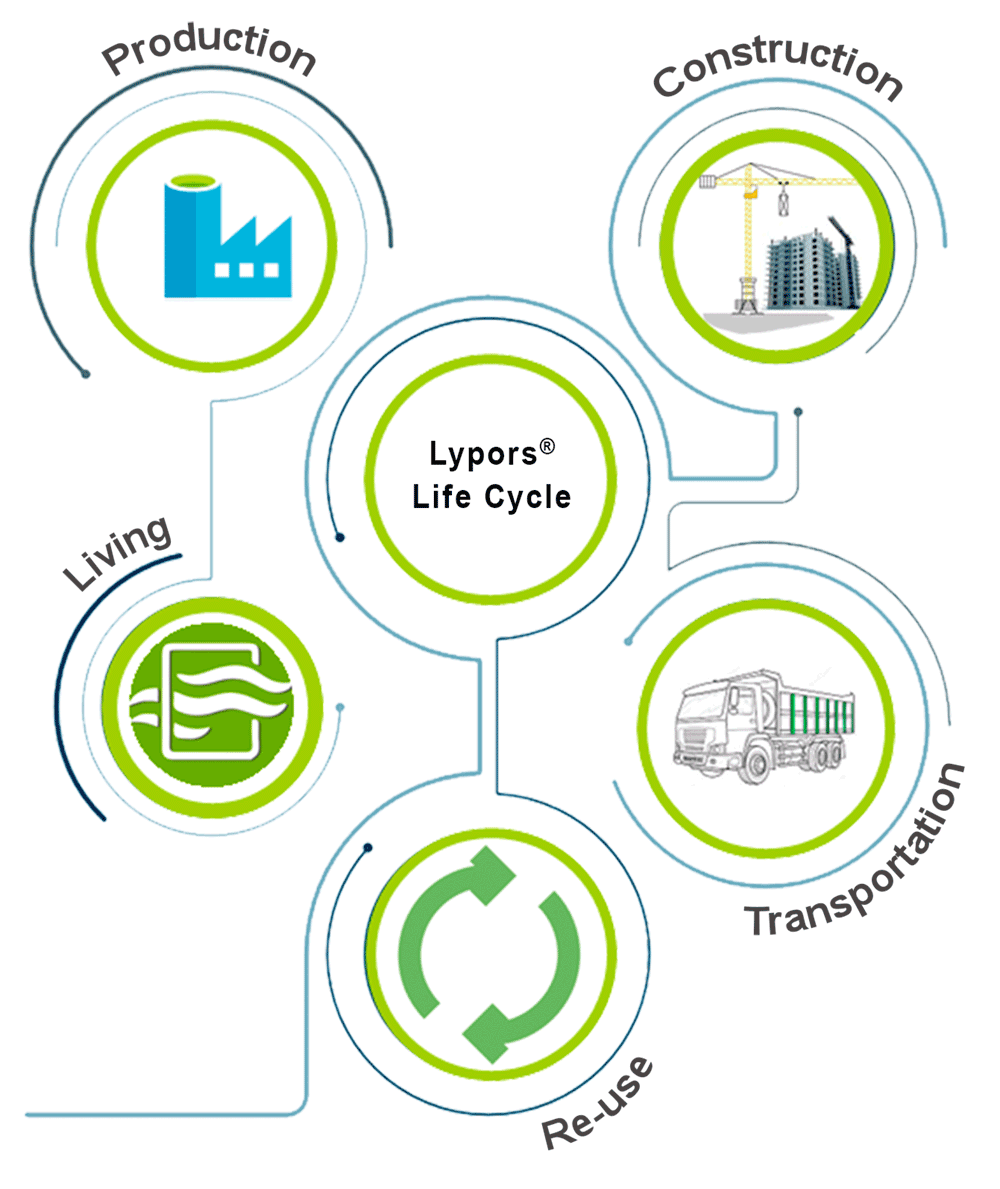

As a Greentech company and a pioneer in upcycling, ZaaK envisions the establishment of a new standard for secondary raw materials on the global market. Lypors® is made from upcycling mineral by-products and wastes such as fly ash, pond ash, deposited ash, biomass, waste to energy ashes as well as bauxite residue and/or the combination of these streams and can be used in various applications.

Coal combustion ash

Lypors® technology is extremely versatile and can handle any types of coal combustion products whether they are freshly produced or deposited, hard coal ash, brown coal ash or a mixture of both ashes.

Biomass-coal co-combustion ashes

Lypors® technology is versatile and handles biomass-coal co- combustion products whether they are freshly produced or deposited.

Waste to energy ash

ZaaK is one of the first companies which started to develop a solution for incineration ashes, also known as waste-to-energy ash, which to a large part until now have been deposited underground.

Bauxite residue

Lypors® technology is extremely flexible and can handle different types of bauxite residue streams whether they are freshly produced or deposited.

Irrespective of the source of the mineral input streams the final product, Lypors®, meets lightweight fine aggregates specifications in accordance with EN 13055:2016 and passes environmental compliances in accordance with CEN/TS 16637-2/3.

Our Solutions.

Together with leading industry players in the design and engineering fields, ZaaK offers tailored Lypors® technology manufacturing concepts to thermal power stations, alumina refineries and waste-to-energy incineration plants.

Lypors® are produced mainly from by-products and wastes. It is available in different size, shape, strength and porosity for different downstream applications.

Lypors® are produced mainly from by-products and wastes. It is available in different size, shape, strength and porosity for different downstream applications.